Cell Shades

ENERGY EFFICIENCY. SOUND ABSORPTION. LIGHT CONTROL.

Cell shades are like a superhero of window treatments: they are energy-efficient, they provide superior sound absorption, and they allow you to control light while maintaining privacy. A&I manufactures custom-cut cell shades, including: single-cell light filtering, single cell room darkening, double cell light filtering, as well as our single cell vintage collection and our classic collection.

Photos

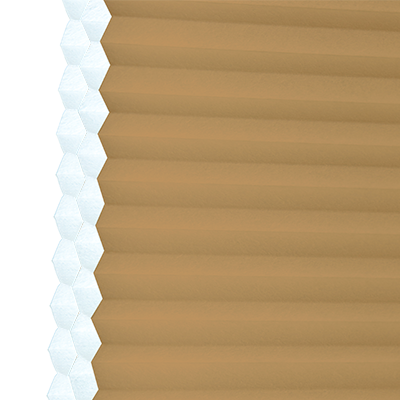

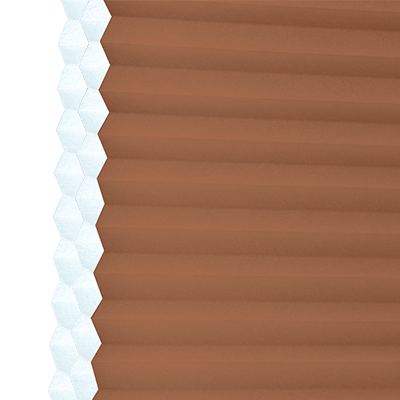

Cell shade Colors

*All colors represented on-screen or in print may not be true to product coloring and can be different than the actual product. If you are concerned about product color, please feel free to order a sample swatch with customer service.

Alabaster - 3/8", 3/4", 7/16"

Anthracite - 3/4"

Antique Pewter - 3/4"

Avocado - 3/4"

Biscuit - 3/8", 3/4", 7/16"

Agate Red - 3/4", 7/16"

Black - 3/4", 7/16"

Bordeaux 3/4", 7/16"

Buff Yellow - 3/4"

Cocoa - 3/4", 7/16", 9/16"

Cotton Fire Retardant - 9/16"

Cotton - 3/8", 3/4", 7/16", 9/16"

Cream - 3/8", 3/4", 7/16"

Dark Chocolate - 3/8", 3/4", 7/16"

Fawn Fire Retardant - 9/16"

Fawn - 3/8", 3/4", 7/16", 9/16

Gray Sheen - 3/4", 7/16"

Jean Blue - 3/4", 7/16"

Marine Blue - 3/4", 7/16"

Ocher - 3/8", 3/4", 7/16"

Onion - 3/8", 3/4", 7/16"

Pongee Fire Retardant - 9/16"

Pongee - 3/8", 3/4", 7/16"

Roseate - 3/4", 7/16"

Royal Gray - 3/4", 7/16"

Slate - 3/4"

Snow White - 3/8", 3/4", 7/16", 9/16"

Spring Green - 3/4", 7/16"

Stone Red - 3/4", 7/16"

Tan - 3/4", 7/16"

Teal - 3/4"

Terra Cotta - 3/4", 7/16"

Water Green - 3/4", 7/16"

White Dove - 3/8", 3/4", 7/16"

Winter White Fire Retardant - 9/16"

Winter White - 3/8", 3/4", 7/16", 9/16

Wisteria - 3/4", 7/16"

3/4” Cordless Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/4” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” High x 1 3/4” Deep extruded aluminum, with PVC end caps. Depth with installation bracket is 2”. |

| Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Bottom Rail | 3/4” High x 1 5/8” deep extruded aluminum with PVC end caps. |

| Cordless Modules | Cordless modules are constructed with clear PVC body. Lift cord is wound inside the module. Steel spring provides tension to pull the shade up. A steel d-rod link all modules together inside the head rail. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Handle | 100% PVC |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limits. |

PRODUCT LIMITS

| Controls (Manual) | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Cordless | 12" | 96" | 10" | *84" |

Maximum Sq. Footage 56 Sq. Ft. Under Warranty

* Exceptions Available Upon Request

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/8” Cordless Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/8” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” High x 1 3/4” Deep extruded aluminum, with PVC end caps. Depth with installation bracket is 2”. |

| Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Bottom Rail | 3/4” High x 1 5/8” deep extruded aluminum with PVC end caps. |

| Cordless Modules | Cordless modules are constructed with clear PVC body. Lift cord is wound inside the module. Steel spring provides tension to pull the shade up. A steel d-rod link all modules together inside the head rail. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Handle | 100% PVC |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limits. |

PRODUCT LIMITS

| Controls (Manual) | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Cordless | 12" | 96" | 10" | *84" |

Maximum Sq. Footage 56 Sq. Ft. Under Warranty

* Exceptions Available Upon Request

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

9/16” Cordless Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 9/16” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” High x 1 3/4” Deep extruded aluminum, with PVC end caps. Depth with installation bracket is 2”. |

| Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Bottom Rail | 3/4” High x 1 5/8” deep extruded aluminum with PVC end caps. |

| Cordless Modules | Cordless modules are constructed with clear PVC body. Lift cord is wound inside the module. Steel spring provides tension to pull the shade up. A steel d-rod link all modules together inside the head rail. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Handle | 100% PVC |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limits. |

PRODUCT LIMITS

| Controls (Manual) | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Cordless | 12" | 96" | 10" | *84" |

Maximum Sq. Footage 56 Sq. Ft. Under Warranty

* Exceptions Available Upon Request

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/4” Cordless Top-Down Bottom-Up Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/4” cells. Non woven fabric. 100% |

| Top Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Mid Headrail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end caps. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Cordless Module | Cordless modules are constructed with clear PVC body. Lift cord is wound inside the module. Steel spring provides tension to pull the shade up. A steel d-rod link all modules together inside the head rail. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Handle | 100% PVC |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls (Manual) | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Top-Down Bottom-Up | 19" | 96" | 10" | *84" |

Maximum Sq. Footage 56 Sq. Ft. Under Warranty

* Exceptions Available Upon Request

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/8” Cordless Top-Down Bottom-Up Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/8” cells. Non woven fabric. 100% |

| Top Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Mid Headrail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end caps. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Cordless Module | Cordless modules are constructed with clear PVC body. Lift cord is wound inside the module. Steel spring provides tension to pull the shade up. A steel d-rod link all modules together inside the head rail. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Handle | 100% PVC |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls (Manual) | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Top-Down Bottom-Up | 19" | 96" | 10" | *84" |

Maximum Sq. Footage 56 Sq. Ft. Under Warranty

* Exceptions Available Upon Request

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

9/16” Cordless Top-Down Bottom-Up Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 9/16” cells. Non woven fabric. 100% |

| Top Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Mid Headrail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end caps. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Cordless Module | Cordless modules are constructed with clear PVC body. Lift cord is wound inside the module. Steel spring provides tension to pull the shade up. A steel d-rod link all modules together inside the head rail. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Handle | 100% PVC |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls (Manual) | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Top-Down Bottom-Up | 19" | 96" | 10" | *84" |

Maximum Sq. Footage 56 Sq. Ft. Under Warranty

* Exceptions Available Upon Request

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/4” Motorized Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/4” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high by 1 3/4” headrail. Deep extruded aluminum, with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” x 1 5/8” deep extruded aluminum with PVC end caps. |

| Motor | Somfy WireFree TL25 Motor powered by an external rechargeable battery pack. Lift Motor is 12v, and comes with .8 Nm of torque at 30 rpm. RTS Communication. |

| Motor Operation | Motor Operation consists of motor, tape drum support, tape drum and tape drum coer. All motor assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Braided polyester of sufficient length to control the raising and lowering of the shade. Outside diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. |

| Control | 1 or 5 Channel Wall Switch or Handheld Remote |

| Charge Cord | Powered by Somfy lithium rechargeable battery pack. Wall charger for external rechargeable battery pack is an 80” cable, with 94 1/2” extension cable available. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Handheld Motorized | 22" | 120" | 12" | 120" |

*Maximum Sq. Footage 96 Sq. Ft. Under Warranty for Single Cell

*Maximum Sq. Footage 75 Sq. Ft. Under Warranty for Double Cell

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/8” Motorized Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/8” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high by 1 3/4” headrail. Deep extruded aluminum, with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” x 1 5/8” deep extruded aluminum with PVC end caps. |

| Motor | Somfy WireFree TL25 Motor powered by an external rechargeable battery pack. Lift Motor is 12v, and comes with .8 Nm of torque at 30 rpm. RTS Communication. |

| Motor Operation | Motor Operation consists of motor, tape drum support, tape drum and tape drum coer. All motor assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Braided polyester of sufficient length to control the raising and lowering of the shade. Outside diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. |

| Control | 1 or 5 Channel Wall Switch or Handheld Remote |

| Charge Cord | Powered by Somfy lithium rechargeable battery pack. Wall charger for external rechargeable battery pack is an 80” cable, with 94 1/2” extension cable available. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Handheld Motorized | 22" | 120" | 12" | 120" |

*Maximum Sq. Footage 96 Sq. Ft. Under Warranty for Single Cell

*Maximum Sq. Footage 75 Sq. Ft. Under Warranty for Double Cell

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

9/16” Motorized Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 9/16” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high by 1 3/4” headrail. Deep extruded aluminum, with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” x 1 5/8” deep extruded aluminum with PVC end caps. |

| Motor | Somfy WireFree TL25 Motor powered by an external rechargeable battery pack. Lift Motor is 12v, and comes with .8 Nm of torque at 30 rpm. RTS Communication. |

| Motor Operation | Motor Operation consists of motor, tape drum support, tape drum and tape drum coer. All motor assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Braided polyester of sufficient length to control the raising and lowering of the shade. Outside diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. |

| Control | 1 or 5 Channel Wall Switch or Handheld Remote |

| Charge Cord | Powered by Somfy lithium rechargeable battery pack. Wall charger for external rechargeable battery pack is an 80” cable, with 94 1/2” extension cable available. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Handheld Motorized | 22" | 120" | 12" | 120" |

*Maximum Sq. Footage 96 Sq. Ft. Under Warranty for Single Cell

*Maximum Sq. Footage 75 Sq. Ft. Under Warranty for Double Cell

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/4” Motorized Wand Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/4” Cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Motor | 12v DC Motor powered by a rechargeable battery pack. |

| Motor Operation | Motor Operation consists of motor, tape drum support, tape drum and tape drum cover. All motor assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Out-side diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Optional Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Motorized Wand | 24" | *120" | 12" | *120" |

*Maximum Sq. Footage 96 Sq. Ft. Under Warranty for Single Cell

*Maximum Sq. Footage 75 Sq. Ft. Under Warranty for Double Cell

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/8” Motorized Wand Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/8” Cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Motor | 12v DC Motor powered by a rechargeable battery pack. |

| Motor Operation | Motor Operation consists of motor, tape drum support, tape drum and tape drum cover. All motor assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Out-side diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Optional Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Motorized Wand | 24" | *120" | 12" | *120" |

*Maximum Sq. Footage 96 Sq. Ft. Under Warranty for Single Cell

*Maximum Sq. Footage 75 Sq. Ft. Under Warranty for Double Cell

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

9/16” Motorized Wand Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 9/16” Cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Motor | 12v DC Motor powered by a rechargeable battery pack. |

| Motor Operation | Motor Operation consists of motor, tape drum support, tape drum and tape drum cover. All motor assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Out-side diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Optional Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Motorized Wand | 24" | *120" | 12" | *120" |

*Maximum Sq. Footage 96 Sq. Ft. Under Warranty for Single Cell

*Maximum Sq. Footage 75 Sq. Ft. Under Warranty for Double Cell

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/4” Lift-ease Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/4” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Clutch Assembly | Clutch assembly consists of clutch, tape drum support, tape drum and tape drum cover. All clutch assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Out-side diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Continuous Cord | 100% polyester. |

| Optional Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Lift-Ease | 12" | 120" | 10" | 120" |

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/8” Lift-ease Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/8” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Clutch Assembly | Clutch assembly consists of clutch, tape drum support, tape drum and tape drum cover. All clutch assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Out-side diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Continuous Cord | 100% polyester. |

| Optional Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Lift-Ease | 12" | 120" | 10" | 120" |

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

9/16” Lift-ease Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 9/16” cells. Non woven fabric. 100% Polyester. |

| Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Clutch Assembly | Clutch assembly consists of clutch, tape drum support, tape drum and tape drum cover. All clutch assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Out-side diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Continuous Cord | 100% polyester. |

| Optional Slat Insert | Cold rolled spring tempered virgin aluminum slat. To have normal width of 1” and be 0.006” thickness after paint. Valance to be finished with a polyester baked enamel. Color coordinated to match the fabric. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Lift-Ease | 12" | 120" | 10" | 120" |

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/4” Lift-ease Top-Down Bottom-Up Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/4” cells. Non woven fabric. 100% Polyester. |

| Top Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Mid Headrail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end caps. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Clutch Assembly | Clutch assembly consists of clutch, tape drum support, tape drum and tape drum cover. All clutch assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Outside diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Continuous Cord | 100% polyester. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Lift-Ease Top-Down Bottom-Up | 23" | 120" | 10" | 120" |

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

3/8” Lift-ease Top-Down Bottom-Up Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 3/8” cells. Non woven fabric. 100% Polyester. |

| Top Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Mid Headrail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end caps. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Clutch Assembly | Clutch assembly consists of clutch, tape drum support, tape drum and tape drum cover. All clutch assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Outside diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Continuous Cord | 100% polyester. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Lift-Ease Top-Down Bottom-Up | 23" | 120" | 10" | 120" |

Compliant with ANSI/WCMA A100.1-2025 Safety Standards

9/16” Lift-ease Top-Down Bottom-Up Cell Shades

PRODUCT SPECIFICATIONS

| General | Assembled by A&I Manufacturing, Inc. Environmentally safe. |

|---|---|

| Fabric | Translucent or Room Darkening spun lace of 9/16” cells. Non woven fabric. 100% Polyester. |

| Top Headrail | 1 1/2” high x 1 3/4” deep extruded aluminum with PVC end caps. Depth with installation bracket is 2”. |

| Mid Headrail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end caps. |

| Bottom Rail | 3/4” high x 1 5/8” deep extruded aluminum with PVC end cap. |

| Clutch Assembly | Clutch assembly consists of clutch, tape drum support, tape drum and tape drum cover. All clutch assembly components are made of PVC. They are linked by a steel square tilt rod. |

| Internal Lift Cord | Shall be braided polyester and of sufficient length to control the raising and lowering of the shade. Outside diameter is 0.9mm. |

| Weights | 100% Steel, Zinc plated with double sided tape. |

| Continuous Cord | 100% polyester. |

| Installation Brackets | Constructed of cold rolled steel. Zinc plated. Hex head screws are included. Intermediate brackets spaced no wider than 36” apart. |

| Fire Safety | Regular cellular shade fabric is not fire retardant. Fire retardant fabric is available upon request. |

| Sizes | Outside mounted window coverings will be made to exact ordered measurements. Inside mounted shades will have 1/4” deducted at the factory from width. See Product Limitations. |

PRODUCT LIMITS

| Controls | Min. Width | Max. Width | Min. Drop | Max. Drop |

|---|---|---|---|---|

| Lift-Ease Top-Down Bottom-Up | 23" | 120" | 10" | 120" |

Compliant with ANSI/WCMA A100.1-2025 Safety Standards